First: Order the Components of the LNA

- Click on the LNA Ordering Parts Info link for the list of components and where the components can be purchased.

- Order a bottle of silicone conformal coating. Although this is not a component of the LNA, you will need to coat your circuit board after you are done soldering everything on. This coating will protect your LNA from moisture, corrosion, fungus, dirt, dust, thermal shock, short circuits, and static discharge. This product is available through Amazon. You can also do a Google search for silicone conformal coating to find other sellers.

Second: Assemble a Soldering Station

- Get a soldering iron and a hot air gun that have temperature controls. The cheap hobby soldering iron will not do. You should set the operating temperature of the soldering iron and hot air gun to 350°C.

- Get a soldering stand. It should consist of a magnifying glass, a light, moveable helping hands, a cleaning sponge, fine tip twezzers, and a cleaning mesh.

- Get a spool of solder. Most solders are a mixture of tin and lead. There are also solders made up of tin and silver, but they melt at a higher temperature and are much harder to use. Solder also comes in different thicknesses or diameters. A thickness of 0.025 inches is a good size for the soldering you’ll be doing.

- The following is a picture of a typical soldering station. It is also called a rework station. The setup shown was purchased from Amazon for about $100. You can also go online and search for soldering irons, hot air guns, rework stations, and soldering stations.

Third: Solder the Components onto the Circuit Board

- There is no best order for soldering the components onto the circuit board. If you are new to soldering, soldering all the components of one type before soldering all the components of another type is a good approach. The following order of soldering is typical for a person new to soldering: capacitors, resistors, inductors, transistors, ICs, SMA connectors, and the cover. Capacitors and resistors are the easiest components to solder onto the circuit board and will give the novice a chance to learn the proper techniques for successful soldering.

- If you have some soldering experience, I would suggest soldering the hardest components first: transistors, ICs, inductors, resistors, capacitors, SMA connectors, and the cover.

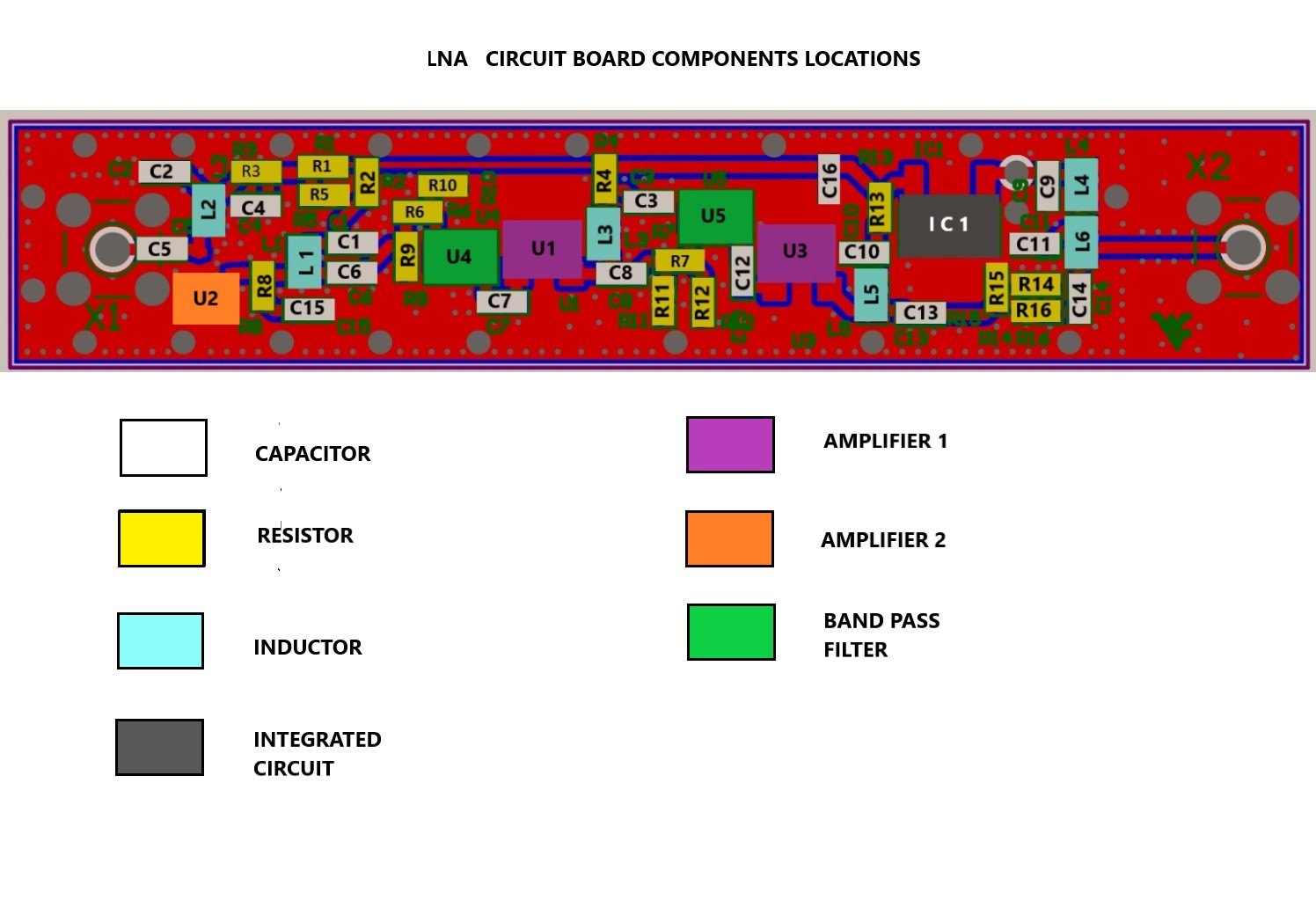

- The following is an easy to read diagram of the circuit board. Each type of component is color coded and labelled. The orientation of each component is also indicated (vertical or horizontal).

Detailed Soldering Instructions for Each Component

Soldering a Capacitor

Place the tip of the soldering iron onto one of the pads and melt a small drop of solder onto the pad. The drop should barely fill the pad. Place one end of the capacitor onto the drop of solder. Touch both the end of the capacitor and drop of solder with the tip of the soldering iron and the heat should melt the solder and the solder should pull the capacitor to the pad. This should make a good connection between the capacitor and pad. Solder the other end of the capacitor to the other pad by touching the tip of the soldering iron to both the pad and the end of the capacitor. Touch the solder to the end of the capacitor and soldering iron. A drop of solder should melt and adhere to the pad and the end of the capacitor. Click on the video link for a demonstration of soldering a capacitor.

https://youtu.be/sOWDIGIjmGE

Soldering a Resistor

Soldering a resistor is identical to soldering a capacitor. You may encounter difficulty in getting solder to melt on the pad. That is because the pad you chose is part of the ground and the ground is the copper that goes all around the circuit board. So you’re heating up a large portion of the circuit board before the pad you’re interested in comes up to the correct temperature. Click on the video link for a demonstration of soldering a resistor.

https://youtu.be/EFwzL3n3f7s

Soldering an Inductor

Soldering an inductor starts the same way as a resistor, a capacitor, or any component to be soldered onto the circuit board: a small drop of solder melted onto a pad. The tricky part of soldering an inductor is that the metal plate is on the bottom of the inductor and not on the side like a resistor or a capacitor. It is important to have the tip of the soldering iron touching the bottom plate of the inductor. It is also important to leave as much room as possible on the other pad. The pad will be soldered to the thin side of the bottom plate of the inductor. Click on the video link for a demonstration of soldering an inductor.

https://youtu.be/9CNtz4u5we0

Soldering a Transistor

There are three different types of transistors to be soldered onto the circuit board. Each one has its own difficulties in soldering onto the circuit board. You sould watch each of the following videos before soldering to determine the orientation of each transistor.

Transistors U1 & U3

https://youtu.be/DP3ABBXyuwY

Transistor U2

https://youtu.be/kvlXMtPB2FY

Transistors U4 & U5

https://youtu.be/xhfXKow-tOs

Soldering an Integrated Circuit (IC)

Soldering an IC is similar to soldering transistors U1 and U3. Click on the video link for a demonstration of soldering an IC.

https://youtu.be/Vwu3AeRIN9w

Soldering the SMA Connectors

There are two SMA connectors on the circuit board: X1 and X2. One SMA connects the antenna feed to the LNA (X1) and the other SMA is the output of the LNA to the AirSpy (X2). Click on the video link for a demonstration of soldering an SMA connector.

https://youtu.be/3jxUv_rlqTI

Soldering on the Protective Cover/RF Shield

The protective cover should not be soldered on until after the LNA is tested and is determined to function properly. Once the protective cover is soldered on, it will be difficult to make any repairs. The protective cover is also hard to remove after it has been soldered on. Click on the video link for a demonstration of soldering on the protective cover.

https://youtu.be/H1GZ_IfYmNQ

Applying the Protective Coating

Applying the silicone conformal coating is the last step for constructing the LNA. Click on the video link for a demonstration of how to cover the LNA with the silicone conformal coating.

https://youtu.be/aINHPuxA2VM